The New Wave of

Corrosion Monitoring

Transform how corrosion is monitored and managed within your organization

Join us at the cutting edge of corrosion technologies.

Answer a few questions to impact the future of corrosion monitoring and prevention.

Acuity reduces material selection time and costly asset downtime.

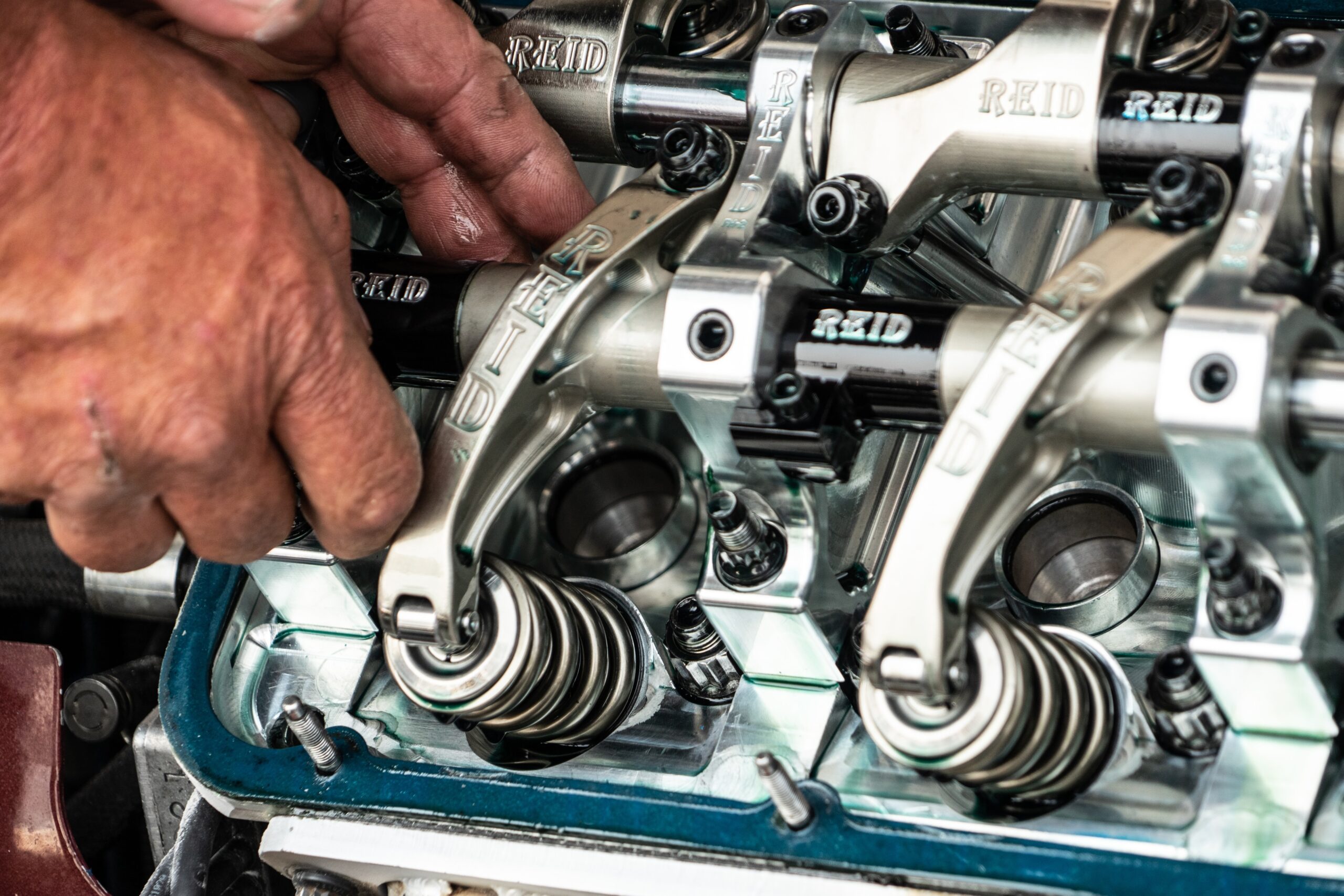

For maintainers, our systems monitor structures and subsystems of aircraft, automobiles, ships, or other assets operating in corrosive environments.

For test and evaluation engineers, Acuity systems accelerate testing time and increase confidence in predicted performance. Our systems operate inside laboratory test chambers, at outdoor exposure sites, and on assets in operation.

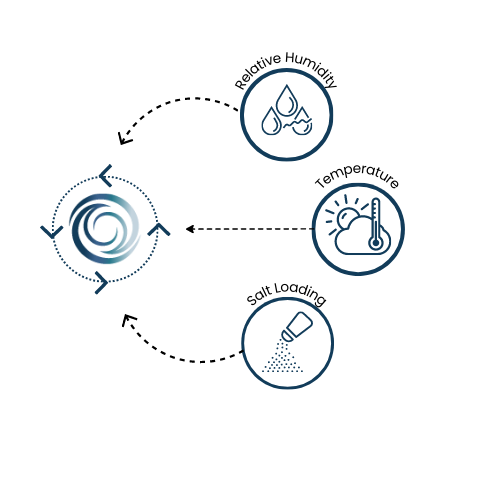

The systems continuously collect and store measurements of:

- Single-alloy corrosion (free corrosion)

- Mixed materials corrosion (galvanic corrosion)

- Surface contaminants (salts)

- Air temperature

- Relative humidity

Solutions by market

For Maintenance Programs

Data-driven Maintenance

Justify the need for visual corrosion inspections based on actual environmental exposure

Early Detection

Detect corrosive conditions throughout an airframe to identify early onset of corrosion

Aircraft Tracking

Analyze how sorties or operations drive corrosive conditions in the aircraft

Full Suite of Corrosion Parameters

Isolate environmental factors which are causing corrosion and degradation of aircraft systems

For Materials & Processes

Environmental Monitoring

Continuously record the environmental conditions that drive corrosion during accelerated and outdoor tests to enhance confidence when interpreting results

Severity Classification

Determine the cumulative severity of any environmental exposure using a common metric

In Situ Coatings Testing

Accelerate testing times and reduce the burden of panel preparation and analysis using continuous and quantified measurements of performance

Continuous Corrosion Rates

Improve assessments of corrosion performance through continuous measurements of damage while monitoring the conditions driving corrosion

Confidence in Materials Selection

Enhance understanding of risk and performance when two dissimilar materials are paired in a corrosive environment

Want Acuity updates?

Subscribe to stay in the know!

Solutions by Industry

Aerospace

Justify the need for inspections and maintenance actions using environmental severity and corrosivity data from the aircraft, preventing unnecessary time-based inspections while detecting early onset of corrosive conditions within the airframe.

Automotive

Acuity systems are used to assess corrosion risk for new vehicle design and the introduction of new materials.

Other

Acuity’s continuous corrosion monitoring can detect corrosion early on, allowing you to take preventative measures and mitigate potential risks to ensure the safety and longevity of your infrastructure, equipment, and materials.

Acuity Resources

Galvanic Compatibility Tool

Use the galvanic compatibility tool below to receive clear guidance on how to determine dissimilar materials compatibility per MIL-STD-889D