Data demonstrates successful use of a predictive coating condition model (PCCM) to assess corrosion protection

Our corrosion technology team was at the DoD SERDP & ESTCP Energy and Environment Innovation Symposium to present data on the successful completion of a four-year Strategic Environmental Research and Development Program (SERDP) project for predicting protective coating failure via statistical modeling.

Along with partners from Georgia Tech, Southwest Research Institute (SwRI), Boeing, the University of Dayton Research Institute (UDRI), and the Air Force Corrosion Prevention and Control Office, the team demonstrated the use of a predictive coating condition model (PCCM) based on a statistical survival analysis to assess corrosion protection. This is a valuable step toward forecasting coating lifetime in relevant outdoor environments that has practical implications to help inform and optimize maintenance planning, thereby reducing costs and increasing asset utilization.

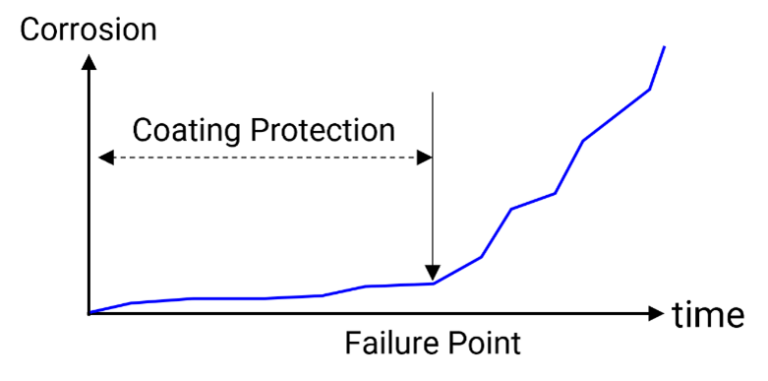

Through continuous monitoring, the failure point (i.e., loss of protective capability) of a coating can be captured to determine an estimate of the coating lifetime (Figure 1). These high-resolution and high-fidelity measurements from Luna Labs’ Acuity™ devices provided valuable testing and training data for the predictive models.

Once a coating has mechanical damage (e.g., a scratch or crack), the only remaining protection is determined by the release of corrosion-inhibiting species. Through extensive laboratory testing of geometries relevant to in-service assets, it was determined that inhibitor protection was the primary means for controlling corrosion as mechanical damage of the coating occurred rapidly. Therefore, the PCCM was trained and tested on samples with induced mechanical damage to forecast the coating lifetime due to the coating’s inhibitor release.

Figure 1: Schematic of a coating lifetime measured via real-time monitoring or prediction of time to coating failure.

In the world of corrosion protection for high-value aerospace and military assets, chromate-containing organic coatings have been the standard for decades. Although they have a long protective life span, they pose significant health hazards for workers and the environment. There are increasing regulations for the elimination of chromates and the substitution of safer, but less effective, non-chromate coating technologies.

The problem? Less is known about the performance and lifetime of these non-chromate coatings in the actual environments where they will be used. How will maintenance schedules need to be adjusted to accommodate the reduced protection and ensure defects are captured earlier? Can computational tools be leveraged to forecast coating lifetime, and therefore help inform long-term maintenance planning?

The work of this research team provides a path forward to full-scale adoption of non-chromate coatings through statistical prediction and forecasting of the coating lifetime under various conditions. Luna Labs’ Acuity Corrosion Technology CR, a novel corrosion monitoring system for evaluating corrosivity and environment in real-time, was used to gather data in cyclic laboratory tests and outdoor settings. This real-time data was then used to develop the PCCM to predict loss of coating protection that was dependent on the severity of the environment.

Next steps include using the PCCM to establish lifetime non-chromate protection guidelines so that appropriate inspection schedules and preventative maintenance can be planned before the onset of coating failure.

Luna Labs US