Acuity’s free web tool provides a rapid visual analysis for ‘go-no go’ material selection decisions.

To address galvanic compatibility of electrically conductive materials, a standardized process has been developed by the DoD for rapid assessment through MIL-STD-889 [1]. The power of assessing the galvanic compatibility is that it can be used for risk-mapping over a specific component [2,3] or entire structure [4].

Historic versions of this standard based the galvanic compatibility assessments on the electrochemical potential in seawater (i.e. the thermodynamic driving force for corrosion), leading to a list of materials ranging from more noble (cathodic) to more active (anodic). However, this process neglected time-dependent kinetic effects such as the corrosion rate. The impact of only using potential is most apparent for titanium, which has a high driving force for corrosion (electropositive potential), but a slow reaction rate on the surface (low current / corrosion rate) [5].

Therefore, a recent D-revision of MIL-STD-889 was led by a team at NAWCAD to incorporate corrosion kinetics into the galvanic compatibility assessment. This important advancement to the historic standard was the result of an enormous amount of data collection and data processing to determine the electrochemical behavior of 47 materials in simulated seawater. Mixed potential theory was used to determine both the electrochemical potential and corrosion rate of each particular material and each material combination. The results were classified into a galvanic compatibility ranking system from zero to six, with increasing severity.

Free Web Tool Supports Recent D-revision

To complement the recent D-revision of MIL-STD-889, Luna Labs developed a free web tool (https://acuitycorrosion.com/products-2/galvanic-compatibility-tool/) to help provide a rapid visual analysis for “go/no go” material selection decisions. In addition, the web tool serves as a resource to access and analyze additional electrochemical behavior measured during the standard revision, but not included in the published standard due to the data size. These data include the electrochemical potential, self-corrosion rates, and polarization behavior of all materials, as well as the galvanic corrosion rates of all material couples. The polarization curves are provided via an interactive graph.

Example Use-Case: Aircraft Designer

An example use-case for this web tool – an aircraft designer whose material design criteria is to maintain alignment with MIL-STD-889D – is given. The first material selection for a fastener assembly may be stainless steel (for the fastener) and an aluminum alloy (for the structure).

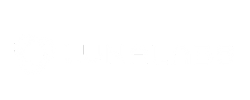

Selecting specifically SS316 and Al2024 in the tool, a visual “go/no go” marker identifies that these materials are not galvanically compatible (Figure 1). In particular, the galvanic compatibility ranking is 5, with 6 being the most severe. Of the selected material couple, the anode has been identified as Al2024 in the third panel, with an estimated galvanic corrosion rate of 12.4 mil/year.

Figure 1: Example use-case with a SS316 / Al2024 material couple selected

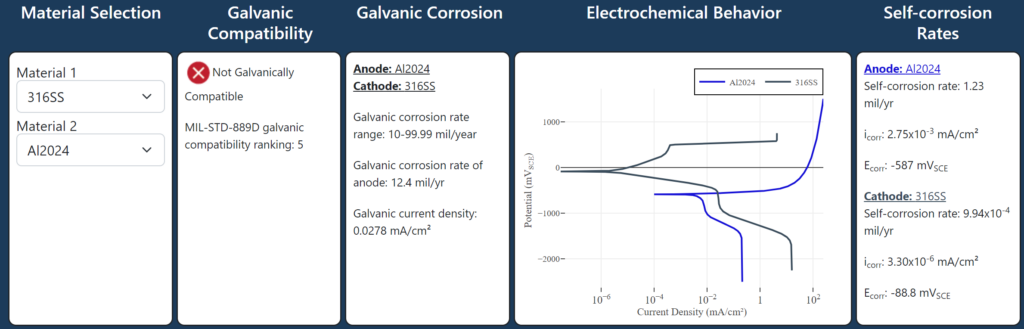

Changing the material selection of the fastener to Ti-6Al-4V, while maintaining Al2024, again identifies that these are not galvanically compatible (Figure 2). However, the galvanic compatibility ranking of 3 is much lower. Comparing the self-corrosion rate of Al2024 in the last panel (1.23 mil/year) to the galvanic corrosion rate of Al2024 in the third panel (1.24 mil/year), it can be determined that this is a weak galvanic couple. The Ti-6Al-4V will only accelerate the Al2024 corrosion by 0.01 mil/year. The aircraft designer may use these results to suggest Ti-6Al-4V as the best option, although both are identified as not galvanically compatible.

Figure 2: Example use-case with a Ti-6Al-4V / Al2024 material couple selected

However, to determine an alternative option to using Al2024 as the structural material, graphite is selected to simulate a carbon fiber reinforced polymer (CFRP) with a SS316 fastener (Figure 3). A green check indicates that this couple is galvanically compatible with a ranking of zero. A galvanic corrosion rate still exists but it is below the threshold of 0.009 mil/year. It is notable that for this selection, the stainless steel fastener is now the anode, and that may also deserve further consideration.

Figure 3: Example use-case with a SS316 / graphite material couple selected

Disclaimer

Per MIL-STD-889D, this table or tool should not be used to indicate the level of risk associated with the galvanic couple nor should it be used to determine the level of protection required to protect the conductive materials. The CEA of appropriate design authority will determine the necessary protection.

References

1] MIL-STD-889D, GALVANIC COMPATIBILITY OF ELECTRICALLY CONDUCTIVE MATERIALS, (2021).

[2] R. Marshall, K.A. Define, R.S. Rosner, A. Goff, C. Sprinkle, P.V. Balachandran, R.G. Kelly, Galvanic Corrosion Between Coated Al Alloy Plate and Stainless Steel Fasteners, Part 2: Application of FEM and Machine Learning to Study Galvanic Current Distributions, Corrosion 79 (2023).

[3] R. Adey, A. Peratta, J. Baynham, T. Curtin, Predicting Cumulative Galvanic Corrosion Damage in Aircraft Structures, in: North Atlantic Treaty Organization Science and Technology Organization, 2018: pp. 1–14.

[4] K.S. Williams, R.J. Thompson, Galvanic corrosion risk mapping, Corrosion 75 (2019) 474–483.

[5] C.A. Matzdorf, W.C. Nickerson, B.C.R. Tronconis, G.S. Frankel, L. Li, R.G. Buchheit, Galvanic test panels for accelerated corrosion testing of coated al alloys: Part 1 – Concept, Corrosion 69 (2013) 1240–1246.